Fanuc Robotics Simulation Software Download

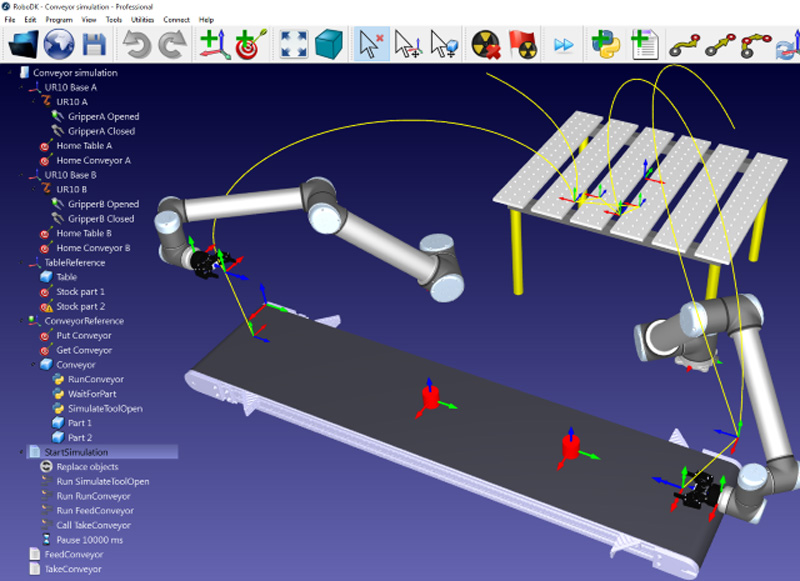

When it’s time to program an industrial robot on the production line, the line has to stop. Because this downtime can cost upwards of thousands of dollars, offline programming (OLP) is an attractive option for many manufacturers. Using simulation software, it’s possible to digitally recreate robots, tools, fixtures, and the entire cell, then define a program complete with motions, tool commands, and logic. That program can be processed and downloaded to the robot, similar to the process of programming any CNC machine with CAM software. Even if line stoppage isn’t a problem, however, there are still cases where designing a robot program in simulation is preferable to manual programming.

FANUC Robotics' ROBOGUIDE family of simulation software packages provide the ability to create, program and simulate a robotic workcell in 3-D, without the need or expense of physical prototypes. Intelligent 3-D robot simulation. FANUC ROBOGUIDE is a robot simulator that simulates both the robot’s motion and application commands, significantly reducing the time it takes to create new motion setups.

FANUC Robotics' ROBOGUIDE family of simulation software packages provide the ability to create, program and simulate a robotic workcell in 3-D, without the need or expense of physical prototypes. Intelligent 3-D robot simulation. FANUC ROBOGUIDE is a robot simulator that simulates both the robot’s motion and application commands, significantly reducing the time it takes to create new motion setups.

For example, in a palletizing application involving dozens or even hundreds of boxes, a typical program could include hundreds of points. Teaching all these points manually would be tedious and time consuming. In these cases, OLP comes into play. According to Heikki Aalto, founder and executive vice president of, the ubiquity of CAD models in today’s manufacturing world means that programming in simulation can begin even before the first product rolls off the line. “When you are designing something, you have the design available for programming at a very early stage. You don’t have the car, the airplane, the product ready yet, but you can do everything based on CAD model beforehand,” he said.

“Once you have your components on the shop floor, you have done your program already.” Choosing the right robotic simulation software involves several important considerations. • Will the software be compatible with the robots and tools in use? • Is the software best suited to the process, such as arc welding or painting? • How much robot programming or CAD experience is required to use the software? • And how much will it cost? In this article, we’ll take a look at several options in the OLP market and some of the critical factors. In the end, you should have a better idea of how to find an OLP solution that will be best for your application.

Cost For the purposes of this article, we’ve divided cost of one seat of the product into three tiers: 0-$10,000; $10,000 - $40,000; and $40,000 and beyond. Because this software is highly customizable, price is variable, and it's important to contact your vendor for an accurate quote. For example, a user planning to simulate one robot performing one process will need a package costing less than a package that can simulate multiple robots of different brands, with extra features like calibration or analysis.

Compatibility Robots. Robot controllers from each vendor perform motion planning differently, so there’s no guarantee that a simulated robot will move the way a real one does.

However, even if the motion of individual axes differs from the simulation, the defined motion of the TCP in cartesian space will be the same. In general, However, whatever OLP solution you choose, it’s safe to say the robot you need to simulate will be supported. In most cases, the specific robot model you need can be added to the simulation from a library. These models are typically provided by the robot manufacturer (eg.,, etc.) If you are working with a smaller or lesser-known robot vendor, it may be more challenging. In OLP software, programs created in simulation can be generated in the proprietary languages for the specific desired robot brand. “When you are happy with the program, you select the specific translator,” said Aalto, “For example, when it comes to KUKA or FANUC there is a pull-down menu, you just select KUKA and then it asks downloading or uploading.

It’s possible to upload a program from a robot on the shop floor as well as to generate native KUKA code to download to the robot.” Tooling. Image source: Packaging Tech Today Tools and end effectors, such as welding guns, grippers or dispensers can be more challenging to simulate accurately. The tool’s parameters are required, as well as the offset of the TCP from the robot flange. A CAD Model of the tool can be used in many cases, but it’s not strictly required. “I could put a balloon on the end of the robot in my model but if I had the ability to control the pattern, the spray pattern and parameters that are driving the calculation of the spray application I would get the same results,” explained Mike Rouman, Senior Marketing Manager in As long as the tool is integrated properly into the robotic cell, I/O calls in the simulation can be done according to the I/O required by the tool manufacturer. In the simulation, an on and off command with a specific I/O can be executed, which will correlate to an arc on/arc off in welding, or plasma on/off for a plasma process, or spray on/off.